PRP2

The Packo stainless steel pumps of the PRP2 series are perfectly cleanable, 3A certified air handling pumps and are mainly used for handling a mixture of air and liquid. Thanks to its unique air handling design based on a standard centrifugal pump, the PRP2 series are particularly suitable as a CIP return pump in the pharmaceutical, biotech and semi-conductor industry.

-

Properties

Property Max. flow 80 m3/h Differential head 75 m wc Max. Inlet pressure 13 bar Viscosity 10 cP Max. temperature 140 °C Impeller type Open Max. free passage 22 mm Max. drive power 22 kW Speed 3000 / 3600 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L for casing and backplate, 1.4435 for the impellers, duplex 1.4462 for metallic parts of the seal and impeller screw Available materials O-ring EPDM, FKM, FEP-FKM, FFKM, Silicone Mechanical seal configuration Single, quench, double Connections Sterile connections Surface finish Pharmaceutical quality, roughness value < 0,4 µm for wetted parts, electropolished and fully certified. Certificates 3A. 1935/2004 EC. FDA. USP. ATEX. EAC -

Description

The Packo stainless steel pumps of the PRP2 series are perfectly cleanable, 3A certified air handling pumps and are mainly used for handling a mixture of air and liquid. Thanks to its unique air handling design based on a standard centrifugal pump, the PRP2 series are particularly suitable as a CIP return pump in the pharmaceutical, biotech and semi-conductor industry.

Pump series PRP2

The pumps of the PRP2 series are perfectly cleanable 3A certified air handling pumps and are mainly used to pump a mixture of liquid and air. These perfectly cleanable pumps have stainless steel 316L pump casings constructed in thick cold rolled plate, 100% non porous and extremely smooth. The pumps have fully machined open impellers constructed in 1.4435 material. Thanks to its crevice-free design and electropolishing as a final surface treatment, the PRP2 pump series are perfectly cleanable, resulting in a reliable component into your production process.

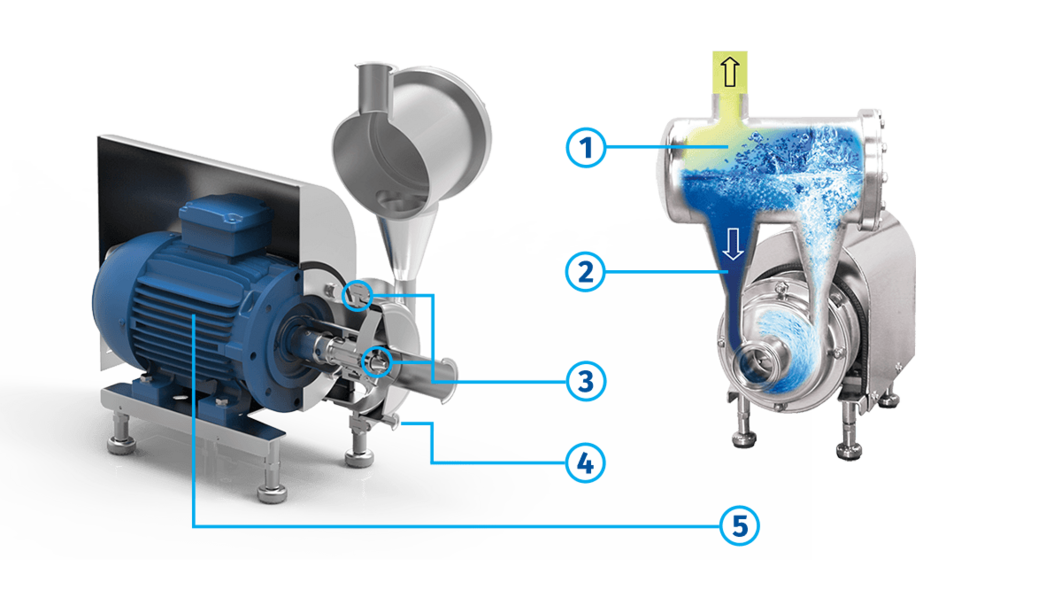

- Electropolished, easy to clean construction, no bacteria traps and no small clearances in order to clean the area around the O-ring

- Unique air handling design with cleanable air separator

- By-pass to casing taking care about air evacuation

- Fully drainable

- Monobloc execution with std. IEC motors

Application areas

Thanks to its unique air handling design based on a standard centrifugal pump, the PRP2 series are particularly suitable as CIP return pump!

Your benefits

- High pump efficiency lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: perfectly cleanable

- Easy & robust construction and easy maintenance: Less downtime

- Limited noise level

- 1 mechanical seal diameter for the entire range

- Fully certified (roughness value, FDA, USP, 3.1 for wetted parts, certificate of conformity, etc.)

- Suitable for SIP

- Parts in contact < 0,4 μm

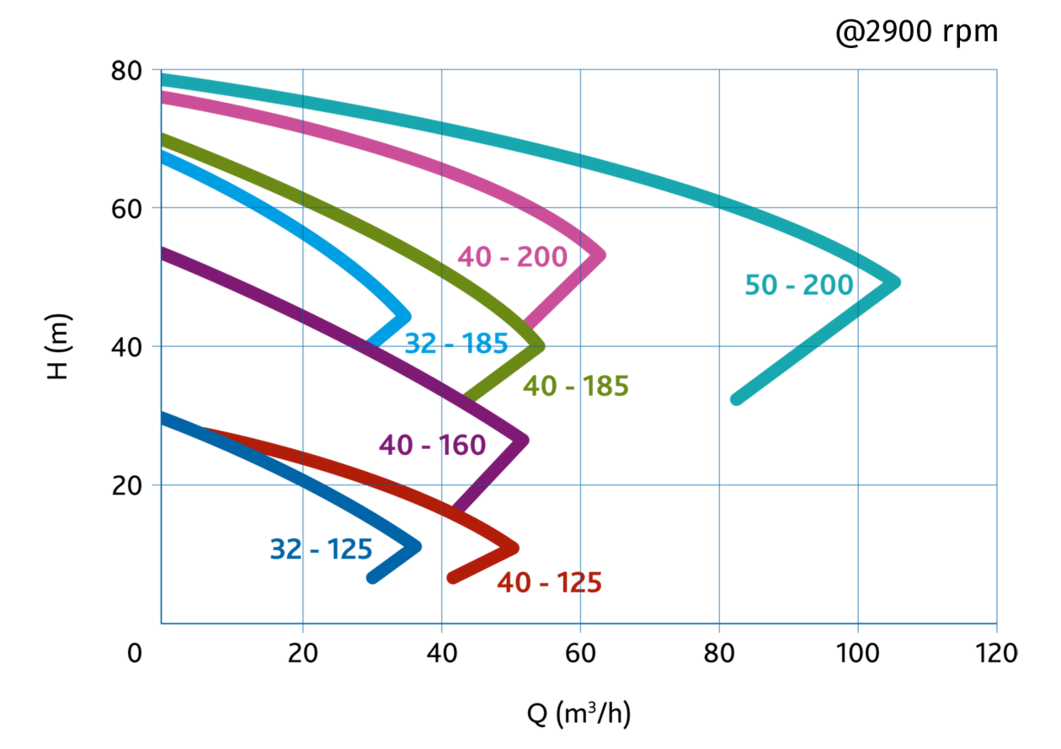

Performance Curves

Assembly and disassembly videos

For all different configurations of this pump series you can find an assembly/disassembly video here. These videos show easy to follow steps to assemble the pumps and replace the seals.

Assembly video - configuration with sterile seal

Disassembly video - replacement of sterile seal

Assembly video - bellows seal configuration

Assembly video - configuration with quench and bellows seal