CRP+

The Packo stainless steel pumps of the CRP+ series are perfectly cleanable EHEDG and 3A certified air handling pumps and are mainly used for handling a mixture of air and liquid. Thanks to its unique air handling design based on a standard centrifugal pump, the CRP series are particularly suitable as a CIP return pump as well as for unloading all type of milkk collecting trucks.

-

Properties

Property Max. flow 105 m3/h Differential head 75 m wc Max. Inlet pressure 13 bar Viscosity 10 cP Max. temperature 140 °C Impeller type Open Max. free passage 22 mm Max. drive power 22 kW Speed 3000 / 3600 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration Single bellow, sterile, quench, double Available material o-ring EPDM, FKM, FEP-FKM, FFKM or similar Connections 3A approved sanitary fittings only Surface finish Hygienic quality, internal welds hand polished + electropolished (wetted parts 0.8 µm) Certificates 3A. 1935/2004 EC. FDA. USP. ATEX. EAC -

Description

The Packo stainless steel pumps of the CRP+ series are perfectly cleanable EHEDG and 3A certified air handling pumps and are mainly used for handling a mixture of air and liquid. Thanks to its unique air handling design based on a standard centrifugal pump, the CRP series are particularly suitable as a CIP return pump as well as for unloading all type of milkk collecting trucks.

Pump series CRP+

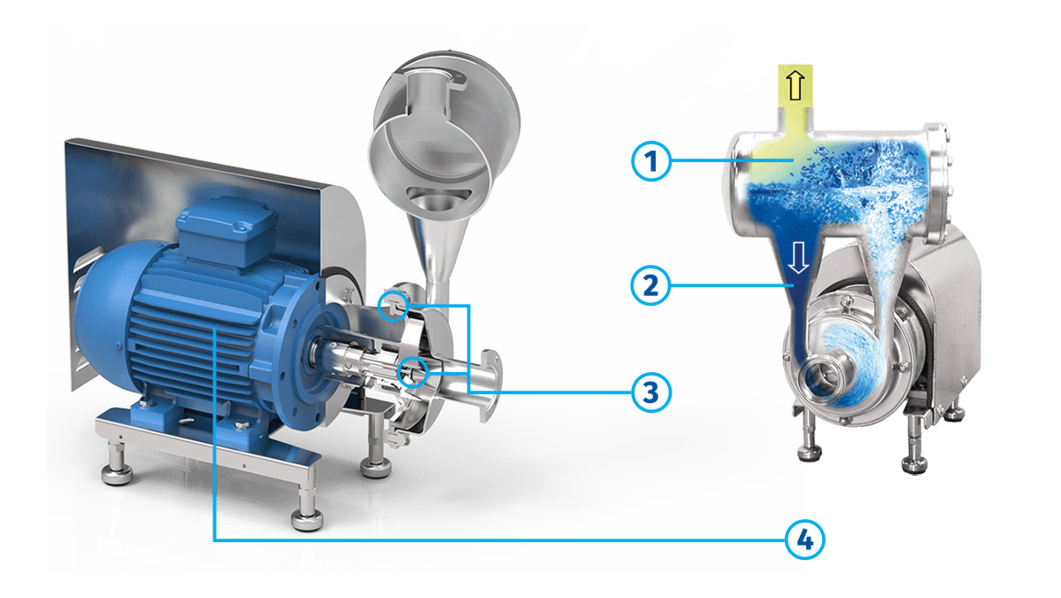

The pumps of the CRP+ series are perfectly cleanable 3A certified air handling pumps and are mainly used to pump a mixture of liquid and air. Constructed in thick cold rolled plate, 100% non-porous and extremely smooth.

The pumps have open investment cast impellers, constructed in 316L or duplex materials. Thanks to its crevice-free design and electropolishing as a final surface treatment, the CRP+ pump series are perfectly cleanable, resulting in a reliable component for your production process.

- Electropolished, easy to clean construction, no bacteria traps and no small clearances in order to clean the area around the O-ring

- Unique air handling design with cleanable air separator

- By-pass to casing taking care about air evacuation

- Monobloc execution with std. IEC motors

Application areas

Thanks to its unique air handling design based on a standard centrifugal pump, the CRP+ series are particularly suitable as a CIP return pump, as well as for unloading applications.

They are used in the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc.

In pharmaceutical and biotech industry they are mainly used for CIP return applications.

Your benefits

- Higher pump efficiency compared with a classic liquid ring pump

- Low NPSH values: less risk on cavitation

- Electropolished: perfectly cleanable

- Easy construction and easy maintenance: less downtime

- Standard components

- Easy to install

- 1 mechanical seal diameter for the entire range

- Robust construction

- Limited noise level

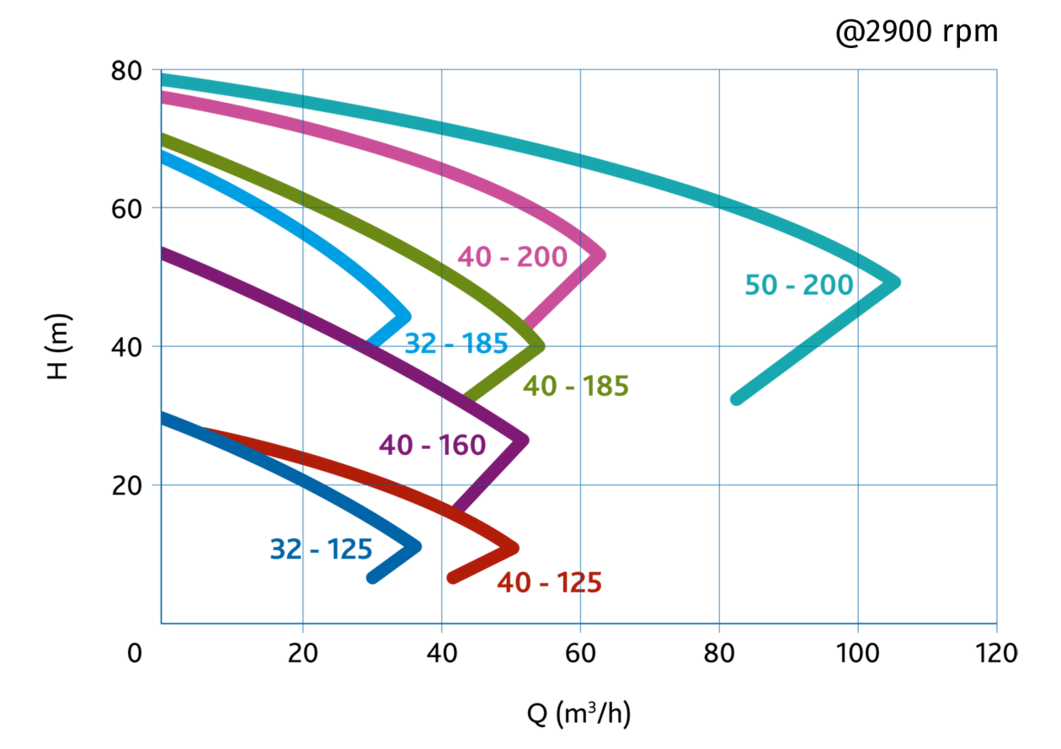

Performance Curves

Assembly and disassembly videos

For all different configurations of the CRP+ series you can find an assembly/disassembly video here. These videos show easy to follow steps to assemble the pumps and replace the seals.

Assembly video - configuration with sterile seal

Disassembly video - replacement of sterile seal

Assembly video - bellows seal configuration

Assembly video - configuration with quench and bellows seal