Food grade pumps for brewing & beverages

A perfect cleanability, high reliability, minimal product damage, low noise and extremely high pump efficiencies resulting in lower energy bills, are some of the most important properties for this field of application.

With a flow rate up to 1800 m³/h Packo Pumps offers just about the widest range of food grade pumps for this market segment. Packo Pumps is heading to become the norm in this market. The fact that the Packo pump for wine and beer filtration became a standard, is the strongest evidence for this. The pumps also meet European regulation 1935/2004 EC.

Typical applications

Wine, beer and fruit juice filtration, gentle pumping of mash as well as handling trub, water, sugar solutions, syrups, extracts, CIP, etc.

Case Studies, application stories & testimonials

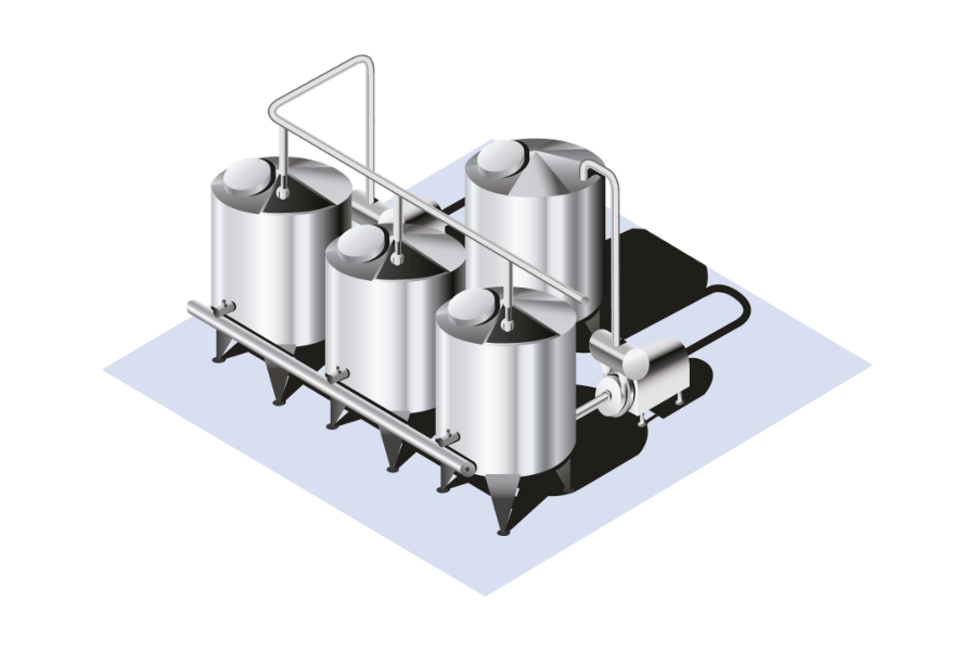

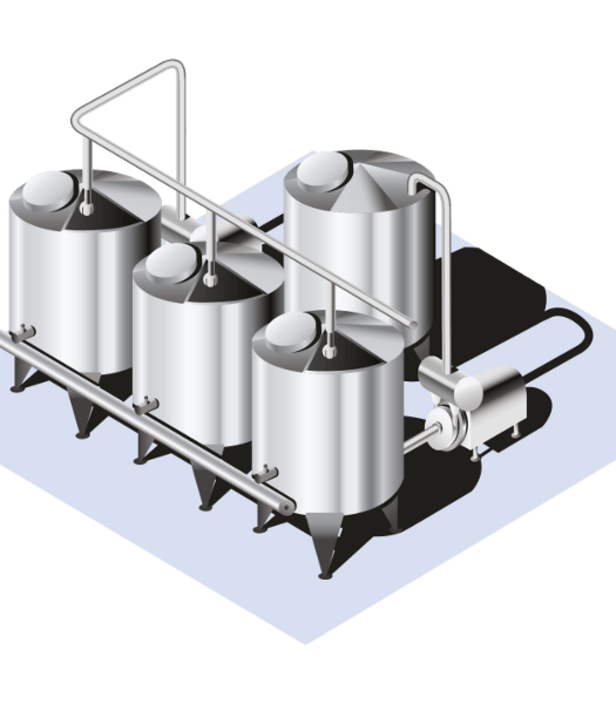

Pumps for the brewhouse

At the start of the brewing process, which takes place in the brewhouse, the following processes take place:

- Scrapping the malt

- Handling, transfering and filtration of mash

(lauter tun & thin bed filtration) - Clarification process

- Wort & trub handling

- CIP

Applications in which several aspects play a role. During the treatment and especially during the filtration of mash, it is very important to select a pump with the highest efficiency. Besides a reduction of the electricity costs, the mash is less damaged, which significantly shortens the filtration time.

As a result, the pumps of the ICP and MCP series are the ideal partner. These pumps are all 1935/2004 EC certified and are therefore suitable for use in the food industry and have a high efficiency and very low NPSH.

Discover our pumps for the brewhouse

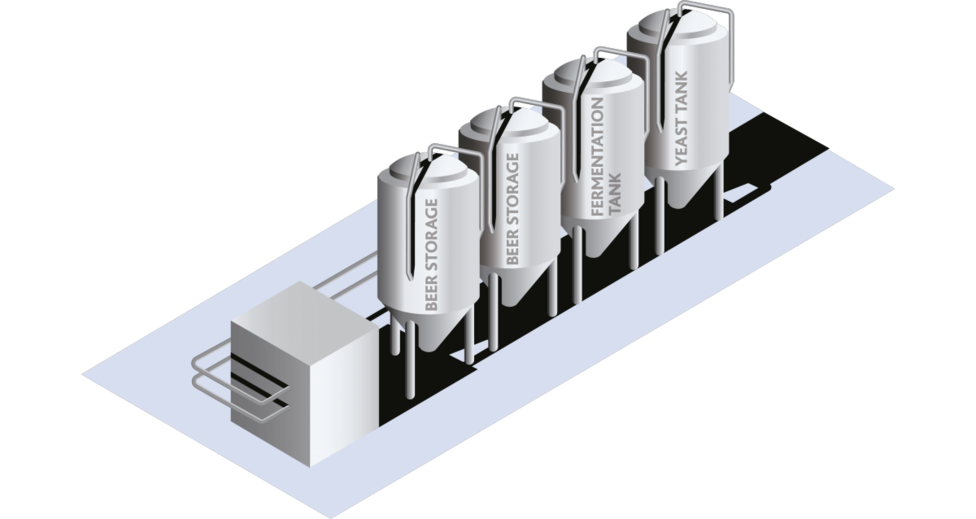

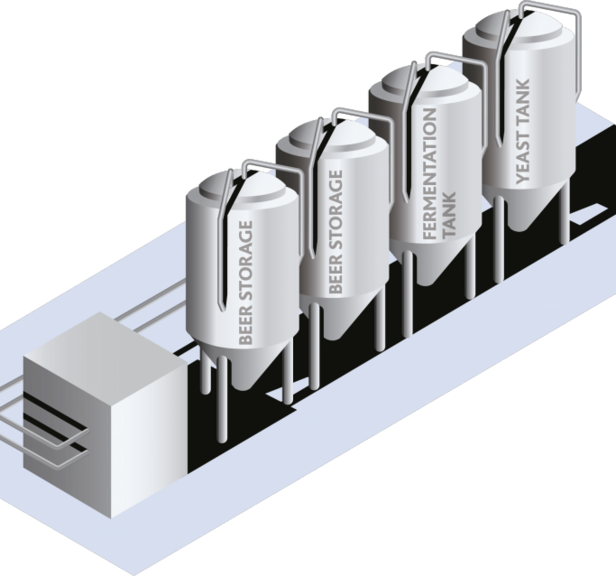

Pumps for the cold process of the brewery

In this part of the brewery you will find, among other things, the following applications:

- Cold wort handling

- Beer filtration (Kieselguhr)

- Brewing carbonisation

- Kegging, bottling & washing

In this part of the brewery, food safety is of the utmost importance and the use of hygienic pumps is a requirement.

Because of their hygiene requirements, our FP and MFP series, which are perfectly cleanable, are the ideal partner in this process.

Some of these series are EHEDG and 3A certified pumps, while all pumps are 1935/2004 EC certified.

Pumps for CIP/SIP

A good CIP in a brewery goes hand in hand with a high level of hygiene to guarantee product safety. Therefore, the CIP return pumps of the CRP & CRP+ series are the appropriate solution.

These air-processing pumps are 3A certified. This way, you can be sure that food safety will never be compromised in your process.

Pumps for waste water treatment

Typical applications are for example, waste water from CIP or cleaning water from crates or bottle cleaning.

The water can be contaminated with glass, paper remnants, fibres, etc. Pump series with specially equipped vortex impellers are available to offer a clog-free solution.

All pumps we offer for this purpose are manufactured in stainless steel with an industrial finish. In this way, we offer a robust, reliable and corrosion-resistant solution to the sometimes aggressive waste water.